TECHNOLOGY: EPISODE 10 LASER DIFFRACTION SYSTEM VS HYDROMETER FOR GRAIN SIZE ANALYSIS

LASER DIFFRACTION SYSTEM Vs HYDROMETER FOR GRAIN SIZE ANALYSIS

This Article was aimed to

validate the usage of the LDS method as a reliable replacement of the hydrometer

method for grain size analysis of fine-grained geo materials. The findings of

this study indicated that the LDS method could be a standalone technique for

particle size analysis of fine geo materials and can reproduce the hydrometer

results with appreciable precision.

Using the Microtrac S3500 LDS

instrument with samples prepared at a concentration of 1.4 g/l in a distilled

water solution, a default refractive index value of 1.75, and without the

addition of a dispersing agent or sonication, the results were proven to be

satisfactory.

Based on the liquid limit of the

samples, a mathematical model was provided to select the distribution method

(either volume or number) to yield the closest results in comparison to the

hydrometer method. Based on the provided equation; any sample with LL >=

180% will result in the number method. However, as a recommendation; this

intermediate ranges to be verified by future studies. Nevertheless, the

provided equation is valid for the liquid limit range used in the current

study.

Further, the sieve analysis for

geo materials is not complicated or time-consuming such as the Hydrometer.

Therefore, and as an unsubstantiated opinion; the authors propose a combined

sieve-LDS method with a correction of the passing percentage (i.e., the LDS

method to be used only for the particles passing the ASTM sieve #200). The

differences between the LDS and hydrometer are qualitatively insignificant

based on the soil classification criteria (both methods yielded the same soil

classification in USCS and AASHTO systems). Quantitatively, the LDS and

hydrometer results regarding silt, clay and colloidal contents and fractal

dimension are comparable to each other and highly correlated. The LDS method

might be considered as a reasonable alternative to the Hydrometer with

comparable results that are fast to obtain, continuous (especially for very

fine particles), independent of particle density and specific gravity, and

generated from the least possible quantity/concentration and efforts. These findings

are applicable to the geo materials range considered in this study, and further

evaluation is required to generalize the findings for geo materials with

different properties.

LASER DIFFRACTION SYSTEM Vs HYDROMETER FOR GRAIN SIZE ANALYSIS

How Laser Diffraction Works

Laser

diffraction is about the relationship between particle size and the angle and

intensity of scattered light. Light scatters more intensely and at smaller

angles off of large particles than small particles. Every analyzer, from the

very first commercial prototype to the state of the art LA-960 utilizes this

principle. In fact, the analyzer itself does not measure particle size -- it

measures the angle and intensity of light scattered from the particles in your

sample. That information is then passed to an algorithm designed to use Mie

Scattering Theory which transforms the scattered light data into particle size

information.

Both

the hardware and software required to make a particle size measurement have

gone through many revisions in order to improve accuracy, precision,

reliability, and ease of use. The LA-960 represents the tenth generation of

HORIBA laser diffraction analyzers; each different and better than the last.

Read on to discover what important factors go into making this measurement

routine and trustworthy.

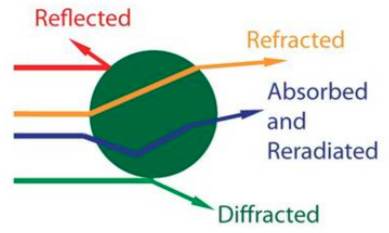

Laser Diffraction Principles

At

the very heart of the laser diffraction technique is the relationship between

light and surfaces (which can be freely interchanged with

"particle" for our purposes). When light strikes a surface it is

either

· Diffracted

· Refracted

· Reflected

· Absorbed

Diffraction

is also known as "edge diffraction" as that is where it occurs.

Refraction occurs as light changes angle traveling through the particle.

We can obtain

information about the size of a particle using the angle and intensity

of scattered light. Diffracted and refracted light is useful for this

purpose; absorbed and reflected light works against this purpose and must be

taken into account during measurement and size calculation.

For particles larger

than a certain size the vast majority of light is scattered by

diffraction. The scattered light is at relatively high intensity and low

angle for these larger particles. The "certain size" is

determined as a multiple of the wavelength of light used for the measurement and

typically approximated at 20 microns. Particles larger than this size

communicate useful size information through diffraction and not refraction.

This means the measurement will not benefit from the use of a refractive

index to accurately interpret refracted light.

For

particles smaller than 20 microns refracted light becomes increasingly

important to calculate an accurate particle size. The scattered light is at

relatively low intensity and wide angle for

these smaller particles. The use of a refractive index and the Mie

scattering theory directly affects accuracy in this size range. All

HORIBA laser diffraction analyzers use the Mie scattering solution by default

and allow the user to input custom refractive index values.